A process is a series of steps and decisions involved in the way work is completed. We may not realize it, but processes are everywhere and in every aspect of our leisure and work.

I would say, to make it more precise, that it is sequence of interdependent and linked procedures which, at every stage, consume one or more resources (employee time, energy, machines, money) to convert inputs (data, material, parts, etc.) into outputs. These outputs then serve as inputs for the next stage until a known goal or end result is reached.

A process consists of four major elements:

Process Improvement

Process improvement involves the business practice of identifying, analyzing and improving existing business processes to optimize performance, meet best practice standards or simply improve quality and the user experience for customers and end-users.

Process improvement can have several different names such as business process management (BPM), business process improvement (BPI), business process re-engineering, continual improvement process (CIP), to name a few. Regardless of the nomenclature, they all pursue the same goal: to minimize errors, reduce waste, improve productivity and streamline efficiency.

Continuous Improvement

Continuous improvement, sometimes called continual improvement, is the ongoing improvement of products, services or processes through incremental and breakthrough improvements. These efforts can seek "incremental" improvement over time or "breakthrough" improvement all at once.

Continuous process improvement (CPI) ensures that your business survives and strives in the long-term. By constantly re-evaluating and improving business processes, your organization will be more efficient, innovative and agile.

If an organization is not continuously improving the way it performs processes, it will likely fall behind in the market.

6 Principles of the Continuous Improvement Model

There are a host of methodologies that businesses use to bring structure to the process of identifying and acting upon opportunities for improvement. You may be familiar with Six Sigma, Kaizen, Lean, Toyota Production System and others. Although these methodologies differ, the heart of each of them is the continuous improvement model.

The continuous improvement model reflects the idea that organizations should undertake incremental improvements to services, products, and processes. It is guided by a few core principles:

Principle 1 – Improvements are based on small changes, not only on major paradigm shifts or new inventions

Principle 2 – Employee ideas are valuable

Principle 3 – Incremental improvements are typically inexpensive to implement

Principle 4 – Employees take ownership and are involved in improvement

Principle 5 – Improvement is reflective

Principle 6 – Improvement is measurable and potentially repeatable

Process improvement techniques

There are several different methodologies designed to help your organization tackle process improvement. Each aims to help your business identify process issues, fix them and analyze the success or failure of those changes.

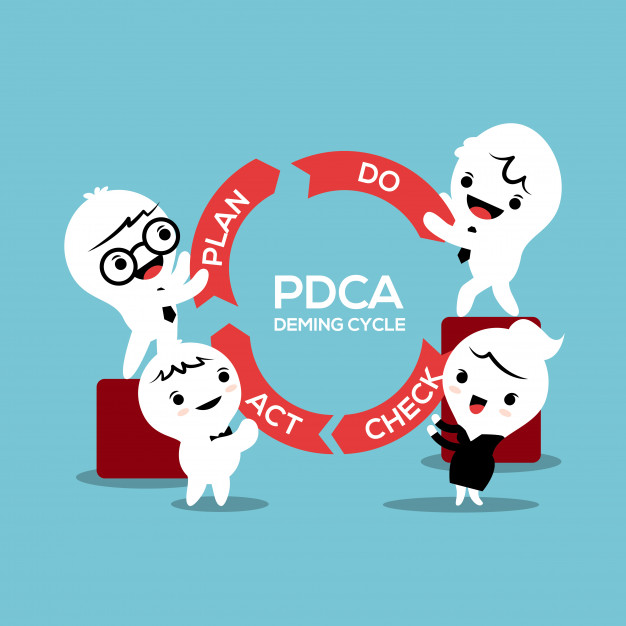

Deming Cycle (PDCA)

Among the most widely used tools for the continuous improvement model is a four-step quality assurance method—the plan-do-check-act (PDCA) cycle, also known as the Deming Cycle (a concept introduced by Dr. Edwards Deming):

Plan: Identify an opportunity and plan for change.

Do: Implement the change on a small scale.

Check: Use data to analyze the results of the change and determine whether it made a difference.

Act: If the change was successful, implement it on a wider scale and continuously assess your results. If the change did not work, begin the cycle again.

Total Quality Management

Total Quality Management (TQM) was huge in the late 1980s and into the 1990s.

So why was TQM big then and isn’t now? Basically, it became unfashionable – it lasted about 10 years, then we needed something else.

TQM was a result of competition from Japan in the 1970s and was firmly focused on manufacturing and Japan’s ability to make high quality goods at a competitive price.

TQM was focused on improving processes to enhance customer satisfaction; and whilst there was no across the board definition of TQM, there was general agreement that the Plan-Do-Check-Act (PDCA) Cycle advocated by Dr W. Edwards Deming should be used along with the following seven basic tools of quality.

Relatively simple and easy to understand, TQM is well suited for individual projects. It is a very good group of tools for problem-solving after things have gone wrong.

Six Sigma

It is a set of techniques and tools for process improvement.

The approach was based on the methods taught by W. Edwards Deming, Walter Shewhart and Ronald Fisher among many others.

It was introduced by American engineer Bill Smith while working at Motorola in 1980.

Six Sigma essentially replaced TQM. It was championed by Jack Welch in 1995 when he was at General Electric and it became central to the GE business strategy. However, Six Sigma was first introduced by engineers at Motorola in 1986 and trademarked in 1993.

The term “Six Sigma” derives from statistical process control and process capability and aims to produce a reject rate of less than 3.4 defects per million opportunities (DPMO).

Six Sigma is now considered to be THE APPROACH to quality improvement. All 500 of the Fortune 500 companies have Six Sigma programs built into their management structure. The successes are well publicized and all of the major consulting groups offer Six Sigma training and services.

This is best for high volume activities where stability is required. The tools are similar to TQM but more structured.

Kaizen

Kaizen is a concept referring to business activities that continuously improve all functions and involve all employees from the CEO to the assembly line workers. Kaizen is the Sino-Japanese word for "improvement".

The Toyota Production System is known for kaizen, where all line personnel are expected to stop their moving production line in case of any abnormality and, along with their supervisor, suggest an improvement to resolve the abnormality which may initiate a kaizen.

The cycle of kaizen activity can be defined as: "Plan → Do → Check → Act". As mentioned above, this is also known as the Shewhart cycle, Deming cycle, or PDCA.

In 1986 Masaaki Imai introduced to the Western world the Japanese term Kaizen and made it famous through his book, Kaizen: The Key to Japan's Competitive Success. Translated in fourteen languages, Kaizen became a fad the world over.

ISO 9001

ISO 9001 is the international standard for a Quality Management System (QMS) and it involves the entire organisation. It is a set of requirements that are recognised globally and are primarily focused on meeting customers’ needs.

Once an organisation has developed and implemented their QMS, they normally are audited by a Certification Body which issues them a certificate that states they comply with ISO 9001. The driver for having a QMS has traditionally been the customer – with customers, including government, requiring their suppliers to have ISO 9001.

ISO 9001, along with other international standards, is updated about every seven to eight years to reflect the changing world. The first ISO 9001 was published in 1987 following the British Standards BS 9000 in 1971, BS 5179 in 1974, and BS 5750 in 1979.

This is great if you want a set of requirements to control your business using a systematic approach, and to demonstrate to others that your organisation has achieved this through being certified.

Haradhan Chattaraj is the Founder, Designated Partner and Head – Infrastructure Services of Luscinia Consulting LLP. He can be reached at haradhan.chattaraj@lusciniaconsulting.com.